Dome Technology invented the dome-construction process using an air-supported membrane. We continue to innovate it while others continue to imitate it.

Dome storage is an ideal solution for your bulk-storage project. The external membrane prevents water and moisture from seeping in, and insulation, concrete, and rebar provide strength and interior climate control.

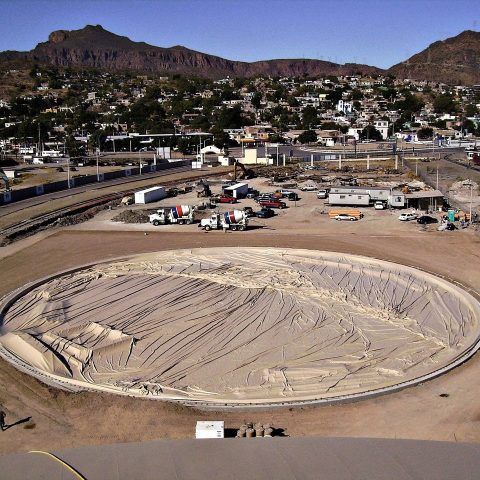

No matter how heavy your load, Dome Technology can customize a foundation system to support it. Based on geotechnical analysis and an understanding of your product, our team provides innovative foundation options for an overall economic system.

There’s also a real need for strong safety shelters. Using the same methods detailed above, Dome Technology constructs many FEMA-rated emergency shelters, which must meet stringent requirements including the ability to withstand projectiles and their impact force. A dome can resist high impact loads without requiring interior beams, thanks largely to our construction process.

Quality checks include materials reception (who received what and verification of quality); mill certification checks; verification that correct drawings are being used for project phases and specifics; and tests for excavations, compactions, and other earthwork. For tunnel installations, superintendents confirm concrete quality and check exact placement for precast sections. For the ring beam, our team verifies accuracy for formwork, rebar, and concrete. And when constructing the dome, foam and primer require their own checklists.